Mobile / Portable Substations

- General

- SKID / FRAME-Mount Substations

- TRAILER-Mount Substations

Mobile / Moveable / Portable

|

IMG focuses on offering its clients custom solution to power supply and distribution. Be it in mining, quarry, oil&gas, renewable energy industrial operations' power needs change as site layout is typically progressive and thus temporary.

The use of mobile or portable power supply / transformation is far more cost effective than the installation of permanent substation structures. Off-site manufacture is also more cost efficient for operations that are located in remote areas and therefore have much higher site installation costs - IMG units arrive at site in plug-and-play ready status.

|

IMG designs and assembles substation units to fit the requirements of site input and output, as well as, environmental conditions. Some sites lend them selves to trailer-mount units, while other sites require skid-mount style substations.

Other sites, typically those in underground environemtns, require units to be compact and more robust to fit into the minimal, yet harsh environments usually found in underground mining or tunneling. (SEE COMPACT, POWER DISTRIBUTION CENTERS)

.

.

|

IMG designs and manufactures various portable power distribution equipment used to convert incoming power in order to supply specific voltages to electrical equipment at site. IMG substation designs vary on the application, customer requirements. Incoming and outgoing connections on substation units can be hard-wired and/or connected via cable couplers or per clients request.

In order to reduce downtime and high onsite costs, IMG designs and manufactures at our shop facilities, complete substations units that are delivered to site plug-and-play ready.

Substation units can be installed in a heavy duty frame enclosure that is delivered to site via trailer and mounted on previously installed pads and/or IMG supplied base frame.

|

Frame-mounted units, usually include a walk-in switchhouse that incorporates the incoming and outgoing sections. The switchhouse provides protection from the elements for equipment, as well as, personelle as they come complete with HVAC system. Transformers can be installed in a cage/fenced-like enclosure for protection.

When sites are not accessible with a trailered unit, IMG substations are assembled on a rigid, steel skid typically consisting of 8x6" tubing skid, point-of-connection for tow/lift hooks, grated floor for non-skid, and oil-containment where required. Outdoor-type enclorures are used for Incoming & Outgoing sections to protect equipment from environemtnal elements.

|

An open skid substations typically consists of an Incoming Section, Transformer Section and Outgoing section. Outgoing section can have 2-3 feeder units that distribute power to various site, electrical equipment.

All IMG susbstations are designed and manufactured with safety in mind. They incorporate key-interlock systems, fast-acting breakers, visual/physical shield barriers, slip-proof flooring, and electronic relays for control and monitoring.

|

IMG designs and manufactures various portable power distribution equipment used to convert incoming power in order to supply specific voltages to electrical equipment at site. IMG substation designs vary on the application, customer requirements. Incoming and outgoing connections on substation units can be hard-wired and/or connected via cable couplers or per clients request.

In order to reduce downtime and high onsite costs, IMG designs and manufactures at our shop facilities, complete substations units that are delivered to site plug-and-play ready.

|

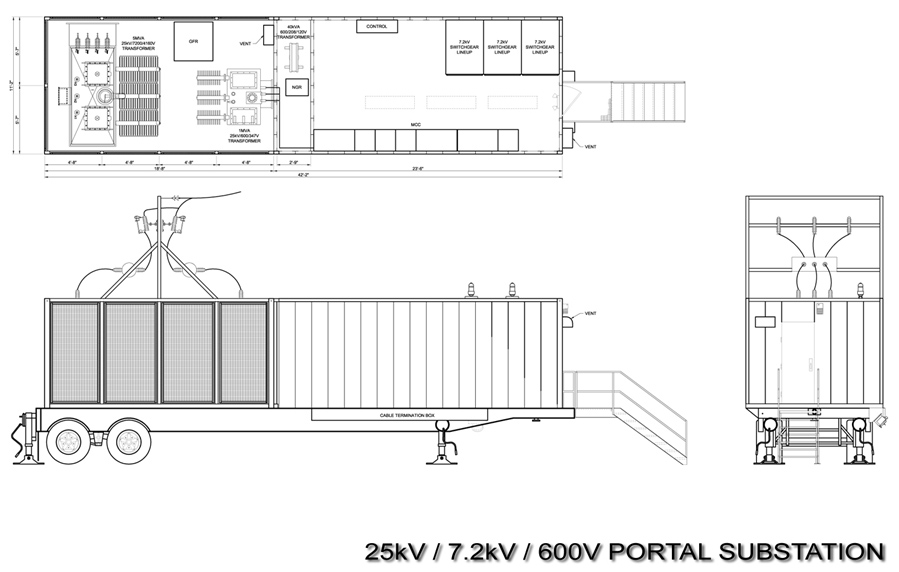

Mobile Substation units are mounted on a commercial-type trailer with dual or triple axle design, dependng he design's weight requirements. These unit usually include a walk-in switchhouse that incorporates the incoming and outgoing sections. The switchhouse provides protection from the elements for equipment, as well as, personelle as they come complete with HVAC system.

|

Transformers can be installed in a cage/fenced-like enclosure for protection.

All IMG susbstations are designed and manufactured with safety in mind. They incorporate key-interlock systems, fast-acting breakers, visual/physical shield barriers, slip-proof flooring, and electronic relays for control and monitoring.

Media / Downloads

- No Media or Downloads

available at this time